Epoxy is a versatile material used for flooring, countertops, and driveways.

We explore the types of epoxy, the benefits of using epoxy on driveways, how to prepare your driveway for epoxy coating, the steps to apply epoxy, and the factors to consider before using epoxy on driveways.

Whether you want to enhance your driveway’s appearance or increase its durability, epoxy may be the solution you need.

What Is Epoxy?

Epoxy is a versatile resin used in various applications for its strong adhesive properties and durability, making it an excellent choice for coating surfaces such as concrete driveways and floors.

Epoxy typically consists of two components – resin and a hardener, which when mixed together form a tough and highly durable material. Its ability to bond well with different substrates like metal, wood, and plastics, makes it a popular choice in industries such as construction, automotive, and aerospace. Apart from providing a protective coating, epoxy is also used for repairing damaged surfaces due to its strong adhesion and resistance to chemicals and moisture.

What Are The Types Of Epoxy?

Epoxy coatings come in various types, each offering unique properties and benefits for different applications such as coatings for driveways and concrete surfaces.

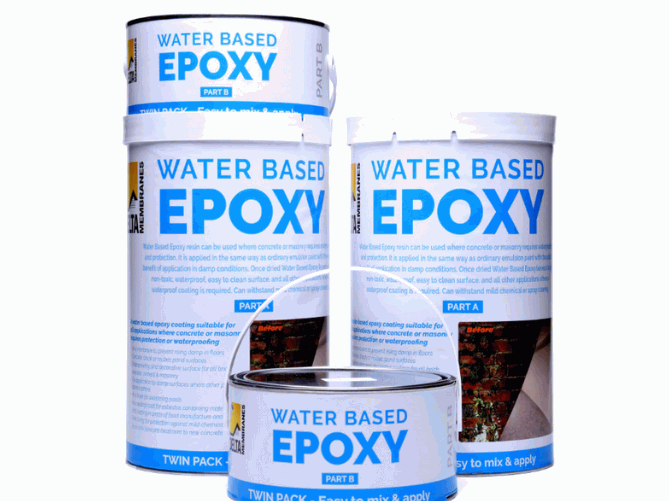

Water-based Epoxy

Water-based epoxy coatings are known for their ease of application and quick drying times, making them an ideal choice for residential driveways and other concrete surfaces.

One of the major advantages of using water-based epoxy is its low VOC content, which makes it environmentally friendly compared to solvent-based alternatives. This not only reduces harmful emissions during application but also creates a safer environment for both the applicator and the inhabitants of the property.

Water-based epoxy coatings provide excellent adhesion to various substrates, offering a durable and long-lasting finish. They are also resistant to chemicals and abrasion, ensuring the surface remains protected in high-traffic areas.

It’s important to note that water-based epoxy may not be as effective as solvent-based options in terms of ultimate durability and resistance to extreme temperatures. This could limit its use in industrial settings or areas exposed to severe conditions.

Solvent-based Epoxy

Solvent-based epoxy coatings are highly durable and resistant to chemicals, making them suitable for industrial driveways and heavy-traffic areas.

These coatings form a tough protective layer that can withstand harsh conditions and heavy loads without chipping or peeling, providing long-lasting protection to the surface beneath. The chemical resistance of solvent-based epoxies makes them ideal for environments where exposure to acids, solvents, and other corrosive substances is common.

Whether it’s a manufacturing facility, warehouse, or garage floor, epoxy coatings offer a reliable solution for enhancing both the aesthetics and functionality of the space. Their seamless finish not only looks sleek but also makes cleaning and maintenance a breeze.

100% Solids Epoxy

100% solids epoxy coatings are extremely durable and provide a thick, protective layer, ideal for both residential and commercial driveways.

One of the key benefits of using 100% solids epoxy is its remarkable thickness, which can range from 10 to 15 mils per coat. This thickness helps create a strong barrier against wear and tear, making it perfect for high-traffic areas like driveways.

In terms of durability, this type of epoxy is resistant to stains, chemicals, and abrasions, ensuring a long-lasting finish that can withstand heavy vehicles and harsh weather conditions.

Common applications for 100% solids epoxy coatings extend beyond driveways to garage floors, industrial settings, and commercial spaces, proving its versatility and reliability in various settings.

Can Epoxy Be Used On Driveways?

Epoxy can indeed be used on driveways, providing a durable and attractive surface that can withstand harsh elements and heavy traffic, enhancing both the look and longevity of your driveway.

Find out more: How Do You Repair A Resin Driveway

What Are The Benefits Of Using Epoxy On Driveways?

Using epoxy on driveways offers numerous benefits, including enhanced durability, reduced maintenance, and improved aesthetics, making it a popular choice for both residential and commercial properties.

One of the key advantages of epoxy driveways is their exceptional resistance to various weather conditions. Whether facing intense sunlight, heavy rain, or freezing temperatures, these driveways maintain their structural integrity and appearance over time.

The smooth and seamless surface created by epoxy makes cleaning a breeze, as dirt and debris can be easily swept away without leaving any residue.

The long-lasting performance of epoxy driveways ensures that they require minimal upkeep and repairs compared to traditional concrete or asphalt surfaces. This durability translates to cost savings in the long run, as homeowners and business owners can enjoy a reliable and attractive driveway for years to come.

How To Prepare Your Driveway For Epoxy Coating?

Proper preparation of your driveway surface is crucial before applying epoxy coating to ensure a smooth and long-lasting finish.

Clean The Surface

The first step in preparing your driveway for an epoxy coating is to thoroughly clean the surface to remove any dirt, debris, or grease that could interfere with adhesion.

One of the most effective methods for cleaning the driveway surface is pressure washing, which uses high-pressure water to blast away stains and grime.

Using a mixture of water and detergent can further enhance the cleaning process, especially for stubborn marks.

Scrubbing the surface with a stiff brush can help loosen embedded dirt and prepare the driveway for a thorough rinse.

Before applying any cleaning solution, it is crucial to read the manufacturer’s instructions to ensure compatibility with the driveway surface material.

By establishing a clean base, you create an optimal foundation for the epoxy coating to adhere to, resulting in a durable and long-lasting finish.

Repair Any Cracks Or Damages

Before applying epoxy, it’s essential to repair any cracks or damages on the driveway to ensure a smooth and even coating.

Repairing cracks and damages in your driveway not only enhances its appearance but also prolongs its lifespan. To start the repair process, you will need some key materials such as a crack filler, a putty knife, a broom, and a wire brush.

- Begin by cleaning the area around the cracks thoroughly to remove any debris and dirt.

- Next, fill the cracks with the appropriate filler, ensuring it is level with the surface.

- Once the filler has dried as per the manufacturer’s instructions, smooth out any excess material and prepare the surface for the epoxy application.

Etch The Surface

Etching the surface is a necessary step to ensure the epoxy adheres properly to the concrete, providing a rough texture for better bonding.

During the etching process, typically, a chemical solution is applied to the concrete surface, which helps remove any contaminants, oils, or other substances that may hinder proper adhesion of the epoxy.

The etching material creates a porous surface by removing a thin layer of the concrete, allowing the epoxy to penetrate and create a strong bond.

This step is crucial in surface preparation before applying the epoxy coating to ensure its durability and longevity, as a properly etched surface significantly enhances the adhesion quality.

What Are The Steps To Apply Epoxy On Driveways?

Applying epoxy on driveways involves several crucial steps to ensure a durable and attractive finish that can withstand the elements and daily wear and tear.

Apply Primer

The first step in applying epoxy to the driveway is to apply a primer, which helps improve adhesion and ensure an even coating.

Primers come in different types such as penetrating and bonding primers. Penetrating primers are ideal for porous surfaces as they seep into the substrate, creating a strong bond. On the other hand, bonding primers are perfect for non-porous surfaces by providing a smooth base for the epoxy coating.

Applying the primer requires thorough cleaning of the surface to remove any dirt, grease, or existing coatings. Once the surface is clean and dry, the primer should be applied evenly using a roller, brush, or sprayer. It’s crucial to follow the manufacturer’s instructions regarding drying times and recoating intervals to achieve optimal adhesion and a lasting finish.

Mix The Epoxy Coating

Properly mixing the epoxy coating is essential for achieving a consistent and durable finish on your driveway.

To mix the epoxy, you should follow the instructions provided by the manufacturer carefully. Typically, a common ratio is to combine equal parts of resin and hardener. Always use measuring tools to ensure accuracy. Utilize a clean container and stir stick for the mixing process. Thoroughly mix the epoxy for at least 2-3 minutes to guarantee a uniform color and texture. Incomplete mixing can lead to inconsistencies in the coating, affecting its adhesion and longevity.

Apply The Epoxy Coating

Once mixed, the epoxy coating should be applied evenly across the driveway to ensure a smooth and durable surface.

Before starting the application process, make sure to clean and prepare the driveway surface thoroughly to remove any dirt, grease, or loose particles. Use a stiff-bristled brush or pressure washer for this purpose. Next, ensure that the surface is dry before applying the epoxy coating.

In terms of tools, you will need a paint roller with a medium nap, a paintbrush for edges and corners, a mixing paddle, a paint tray, gloves, and safety goggles. Mixing the epoxy according to the manufacturer’s instructions is crucial for its proper application.

Start by cutting in the edges and corners using the paintbrush before applying the epoxy coating with the roller. Work in small sections to maintain control and ensure an even spread. Avoid over-application, as it can lead to drips and uneven spots.

Apply A Second Coat (Optional)

Applying a second coat of epoxy can enhance the durability and appearance of your driveway, although it is an optional step.

One of the primary benefits of adding a second coat of epoxy is that it provides an extra layer of protection against wear and tear, extending the lifespan of your surface. This additional coat acts as a barrier, shielding your driveway from harsh weather conditions, chemicals, and UV rays, ultimately reducing the chances of chipping or peeling.

Timing is crucial when it comes to applying the second coat of epoxy. It is recommended to wait until the first coat is completely dry but still tacky to the touch. This timeframe typically ranges between 4 to 24 hours, depending on the specific product used. Applying the second coat too early or too late can result in poor adhesion and affect the overall finish.

When applying the second coat, it is essential to use the correct technique to ensure a smooth and even coverage. Start by thoroughly mixing the epoxy components according to the manufacturer’s instructions to guarantee proper curing. Use a high-quality synthetic brush or roller to apply the second coat in a consistent manner, working in small sections to avoid streaks or uneven patches.

Add Decorative Elements (Optional)

Adding decorative elements to your epoxy-coated driveway can enhance its aesthetic appeal, offering a customized look that matches your home’s style.

In terms of enhancing the visual appeal of your driveway, there are several types of decorative elements you can consider incorporating. This could include colored aggregates, metallic flakes, or even stenciled patterns. The process of adding these elements involves mixing them into the epoxy coating before it is applied to the driveway surface. These decorative elements not only add flair to your driveway but also provide functional benefits.

What Are The Factors To Consider Before Using Epoxy On Driveways?

Before using epoxy on driveways, several factors must be considered, including climate conditions, traffic load, and maintenance requirements to ensure optimal performance and longevity.

Climate And Temperature

The climate and temperature in your region play a significant role in the performance and longevity of epoxy coatings on driveways.

Hot climates can cause the epoxy to cure too quickly, leading to a weak bond and potential failure. On the other hand, extreme cold temperatures can prevent proper curing, resulting in a brittle finish that is prone to cracking.

In regions with high humidity, moisture can interfere with the epoxy adhesion, causing bubbling or delamination over time. Conversely, dry climates may necessitate additional measures to prevent rapid evaporation during application.

Traffic And Usage

The amount of traffic and specific usage patterns of your driveway will influence the type of epoxy coating needed to ensure long-lasting performance.

For driveways experiencing heavy vehicle traffic on a daily basis, a high-traffic epoxy coating with exceptional durability is crucial to withstand wear and tear. Likewise, driveways with infrequent use may not require such robust coatings, making a standard or medium-traffic epoxy a more cost-effective option.

Considering the frequency of use is vital in determining the optimal epoxy solution for your driveway. Improper selection can result in premature deterioration, frequent repairs, and higher maintenance costs. Therefore, assessing your specific traffic load and usage patterns is essential in selecting the right epoxy coating that best suits your needs.

Maintenance And Durability

Regular maintenance is essential to preserve the durability and appearance of an epoxy-coated driveway, ensuring it remains in good condition for years to come.

For maintaining an epoxy-coated driveway, routine cleaning is crucial. This involves sweeping away debris regularly to prevent scratching the surface. Additionally, pressure washing with a mild detergent can help remove tough stains without damaging the epoxy coating. It’s important to avoid using harsh chemicals or abrasive cleaning tools as they can cause deterioration. In terms of repairs, any chipped or damaged areas should be addressed promptly to prevent further deterioration. Regular inspections can help catch issues early, ensuring the driveway stays looking pristine.