Silicone render is gaining popularity in contemporary construction and home improvement projects due to its remarkable durability and kerb appeal. This material presents a variety of advantages, including its hydrophobic surface, breathable properties, and minimal maintenance requirements. For those considering the application of paint on silicone render, this guide outlines the essential materials needed, the preparation process, and a comprehensive step-by-step approach to painting techniques. Furthermore, it will provide valuable insights on how to maintain the painted surface to ensure lasting beauty and prevent discolouration algae. This guide aims to equip you with all the necessary information, including proper surface preparation and paint application techniques, for a successful project.

What Is Silicone Render?

Silicone render is a contemporary finishing material specifically designed for exterior walls, offering a durable and flexible barrier against various environmental elements. It utilizes advanced technology to create a hydrophobic surface that minimizes moisture ingress while permitting the walls to breathe, which is essential for maintaining the structural integrity of homes and properties. Additionally, its breathable properties contribute to its effectiveness as an exterior wall insulation material.

In contrast to traditional rendering methods, silicone render provides superior paint adhesion and resistance to UV degradation, ensuring a long-lasting finish that enhances kerb appeal. This innovative solution is particularly suitable for homeowners seeking both aesthetic and functional advantages, making it a preferred choice in the variable climate of the UK.

Take a look: What Is The Best Insulation For External Walls

What Are The Benefits Of Using Silicone Render?

Utilizing silicone render presents several advantages that notably enhance both the aesthetics and durability of exterior surfaces. A key benefit is its resilient finish, which effectively safeguards structures against moisture damage and UV degradation, thereby prolonging the lifespan of the render itself.

Furthermore, silicone paint can improve the hydrophobic characteristics of the render, allowing water to bead off instead of infiltrating the surface. This low-maintenance solution is particularly suitable for homeowners seeking to reduce upkeep while preserving curb appeal, rendering it a favored option among rendering professionals.

Durable And Long-lasting

Silicone render is widely recognized for its durable finish, offering robust protection against moisture damage and UV degradation, thereby making it an ideal choice for exterior wall insulation in residential and commercial properties.

The exceptional resilience of silicone render is attributed to advanced technology that ensures its long-lasting effectiveness. This innovative coating system establishes a waterproof barrier, significantly mitigating the risk of mold and mildew that traditional rendering techniques often fail to address. In contrast to standard cement renders, which may develop cracks over time, silicone solutions provide superior flexibility, allowing them to expand and contract in response to varying temperatures.

Key advantages include:

- Enhanced resistance to pollution and weathering

- Reduced maintenance requirements due to self-cleaning properties

- Color retention that exceeds that of many conventional rendering options

This durability translates to increased longevity and reduced frequency of repairs, making it a prudent investment for homeowners seeking sustainable solutions.

Water-resistant

A notable feature of silicone render is its water-resistant properties, which arise from its hydrophobic surface that effectively repels moisture ingress.

This water-repellent capability is essential for maintaining the integrity of various structures by preventing dampness and subsequent mold growth. Mold presents not only health risks but can also result in costly repairs and compromise structural integrity over time. By employing silicone render, builders can significantly mitigate the likelihood of such issues occurring.

The application of silicone paint can further enhance these protective qualities. Silicone paint serves as a barrier, improving water-resistant capabilities and ensuring a longer-lasting and aesthetically pleasing finish.

Ideal applications for silicone render and paint include:

- Exterior walls in humid climates

- Basements and moisture-prone areas

- Building facades exposed to heavy rainfall

Utilizing these innovative materials not only safeguards structures but also promotes sustainable building practices by reducing maintenance requirements.

Flexible

The flexibility of silicone render is a critical attribute that enables it to adapt to the natural movements of buildings, thereby ensuring that paint adhesion remains intact and minimizing the risk of cracking.

In contrast to traditional rendering methods, which tend to be rigid and are susceptible to fracturing under pressure, silicone render demonstrates remarkable adaptability to thermal expansion and contraction. This characteristic is particularly significant in regions that experience extreme weather variations, where materials may be subjected to stress from fluctuating temperatures.

For example, in humid environments, the capacity of silicone render to resist moisture without compromising structural integrity is essential. In arid climates, its breathability aids in preventing trapped moisture, thereby mitigating the risk of facade deterioration.

Consequently, these properties not only enhance the aesthetic appeal of a building but also significantly extend the lifespan of the finish, making flexible silicone render a prudent investment for both homeowners and builders.

Low Maintenance

Silicone render necessitates minimal maintenance in comparison to traditional rendering methods, which often require frequent repairs and repainting.

This low-maintenance quality is particularly attractive to homeowners and property managers, as it significantly reduces ongoing upkeep efforts, especially in the variable UK weather. A key advantage of silicone render is its exceptional resistance to algae and discoloration, which ensures that surfaces remain vibrant and visually appealing for prolonged periods.

- Cleaning silicone render is a straightforward process; most dirt and grime can be easily removed.

- A pressure washer serves as an effective tool for this purpose, simplifying the task without the need for extensive scrubbing.

Applying high-quality paint, such as Emperor Masonry Paint, can further enhance the longevity of the render’s appearance, providing an additional barrier against environmental elements and extending its fresh look. The durability and ease of care associated with silicone render make it a prudent choice for contemporary building projects.

What Materials Do You Need For Painting Silicone Render?

To achieve optimal results when painting silicone render, it is essential to utilize several key materials, including high-quality paint that is compatible with the render’s characteristics. This ensures proper application and enhances the longevity of the paint.

High-quality Paint

Selecting high-quality paint is crucial when applying it to silicone render, as it significantly enhances both the durability and aesthetic appeal of the finish. The appropriate choice not only elevates the visual attractiveness but also contributes to the functionality of the exterior surfaces.

Silicone paint is particularly notable for its exceptional properties, including water repellency and breathability, which allow moisture to escape while effectively preventing water penetration. Additionally, breathable paint options like Johnstones Stormshield can offer an excellent finish. This characteristic is especially advantageous in environments with unpredictable weather conditions. The range of available colors is extensive, catering to diverse preferences while ensuring optimal performance under UV exposure.

Key benefits of silicone paint include:

- Excellent adhesion to silicone surfaces

- Resilience against fading and chalking

- Resistance to mildew and algae

The combination of high-quality silicone paint with silicone render results in a durable solution that merges beauty with protection, ensuring that exteriors remain vibrant and intact for years to come.

Paint Brushes And Rollers

Utilizing the appropriate paint brushes and rollers is crucial for attaining an even finish when applying paint to silicone render. The choice of tools can significantly impact the overall appearance and durability of the painted surface, ensuring that the inherent properties of silicone are preserved while enhancing the aesthetic appeal of the exterior.

There are various types of brushes and rollers specifically designed for use with silicone render. High-quality synthetic brushes are frequently recommended for their capacity to hold paint effectively and deliver a smooth application. For larger areas, a thick-napped roller can efficiently distribute paint, thereby minimizing roller marks.

- Brushes: It is advisable to select a brush with synthetic bristles, ideally 2 to 4 inches wide, to ensure better control when cutting in edges and corners.

- Rollers: A roller with a medium pile (approximately 10-12 mm) is recommended to ensure proper paint penetration into the texture of the render.

When applying paint, it is essential to use a good quality paint and maintain a wet edge while avoiding overloading the brush or roller to prevent drips. Working in sections will help maintain a consistent finish, and allowing adequate drying time between coats is vital for achieving a professional appearance, especially in outdoor applications where UV degradation could be a concern.

Paint Tray

A paint tray is an essential tool that enhances the efficiency of paint application, providing improved control and minimizing mess during the painting process. This is particularly important when using specialty paints like acrylic paint or mineral paint that require precise application.

Utilizing a paint tray significantly increases the ability to manage paint, particularly when working with specialty products such as silicone paint that require precision. By containing the paint within an easily accessible shallow basin, a paint tray aids in achieving an even distribution on the roller, ensuring optimal coverage without the risk of overflow. This approach is also effective with known brands like Johnstones Stormshield and Emperor Masonry Paint, providing a tidy painting experience, which is highly valued by both homeowners and professionals. The use of a paint tray can effectively prevent unwanted spills and drips, which are commonly associated with direct application from a paint can.

Key advantages of using a paint tray include:

- Providing a reliable platform for loading paint.

- Reducing the risk of overloading applicators.

- Helping maintain a clean work area.

Through these benefits, a paint tray proves to be critical in facilitating a smooth and effective painting endeavor.

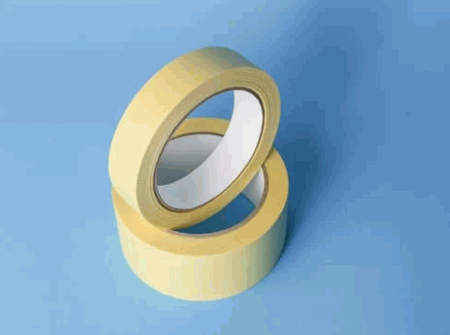

Masking Tape

Masking tape is an essential tool in the painting process, as it ensures clean lines and protects areas that should not be painted.

When utilized correctly, this straightforward yet effective tool can elevate a basic paint job to a level that resembles professional workmanship, enhancing the overall aesthetic of a space. The technique involves applying the tape not only to the edges but also over surfaces that require protection, making it imperative to select the appropriate type for the specific project.

- For delicate surfaces, it is advisable to use low-tack tape.

- Ensure that the surface is clean and dry prior to application.

- Press down firmly on the edges to create a seal that prevents any paint seepage.

It is important to note that achieving clean lines is heavily dependent on meticulous application, as even the slightest gap can result in unsightly paint bleed, undermining the professional appearance of the finished work.

Ladder Or Scaffolding

When applying silicone render on taller structures, the use of a ladder or scaffolding is essential to ensure both accessibility and safety throughout the painting process.

Working at heights presents inherent risks, making the prioritization of safety paramount. Selecting the appropriate equipment is vital; a sturdy ladder or suitable scaffolding not only provides necessary support but also extends the worker’s reach effectively.

To ensure optimal safety, it is imperative to inspect the equipment for any damage prior to use and to position it on a stable, level surface to mitigate the risk of accidents.

- Always maintain three points of contact while climbing.

- Utilize safety harnesses when necessary.

- Remain aware of your surroundings to avoid obstacles or electrical hazards.

By adhering to these guidelines during the painting process, one can significantly reduce risks and facilitate a successful project, irrespective of the height involved.

How To Prepare The Silicone Render For Painting?

Proper surface preparation is essential for ensuring the longevity and aesthetic appeal of painted silicone render. This process, often recommended by render experts, involves several crucial steps, including:

- Thorough cleaning of the surface,

- Repairing any damaged areas, and

- Applying a suitable primer prior to the application of the render.

Clean The Surface

The initial step in preparing silicone render for painting involves a thorough cleaning of the surface, potentially utilizing a fungicidal cleaner from suppliers to address any mold or algae buildup that may lead to moisture damage.

To achieve optimal results, it is crucial to ensure that the surface is devoid of any debris, dirt, or existing paint layers that could adversely affect adhesion. A gentle pressure washer can be an effective tool for this purpose, as it efficiently removes loose contaminants. Additionally, scrubbing with a stiff-bristled brush while applying an appropriate cleaning solution aids in the removal of stubborn stains that may not be eliminated through washing alone. After the surface has been adequately cleaned, it is important to allow it to dry completely, as this can significantly enhance the performance of the paint.

- If a pressure washer is not available, a mild detergent combined with water may be used.

- It is advisable to rinse the area thoroughly to ensure that all residues are removed prior to painting.

- After cleaning, inspect the surface to identify any remaining issues that require attention.

By following these guidelines and prioritizing the cleanliness of the surface, one sets the foundation for a durable and aesthetically pleasing paint job that is capable of withstanding the test of time.

Repair Any Damaged Areas

After cleaning, it is essential to repair any damaged areas of the silicone render in order to maintain a smooth and even surface for painting.

Neglecting to address imperfections may lead to more significant issues in the future, which can adversely affect not only the aesthetic appeal but also the structural integrity of the surface. Begin by conducting a thorough inspection of the render for any cracks, holes, or other defects. If any are identified, it is advisable to fill these areas with a high-quality, flexible silicone sealant specifically designed for exterior applications. This type of sealant is capable of adapting to temperature fluctuations and movement, thereby ensuring a long-lasting repair.

- Start by removing any loose debris from the damaged areas.

- Apply the flexible silicone carefully into the cracks, ensuring that it fills the void completely.

- Utilize a smoothing tool or your finger to create a seamless finish that blends with the existing surface.

By adhering to these steps, one can effectively enhance the durability and visual quality of the render prior to proceeding with any painting or finishing touches.

Prime The Surface

Priming the surface prior to painting silicone render is essential for improving paint adhesion and ensuring a uniform finish, crucial for preventing colour change due to UK weather conditions.

By utilizing a high-quality primer specifically designed for silicone render, one can significantly enhance both the durability and vibrancy of the paint application. An appropriate primer functions as a barrier, effectively smoothing out imperfections and creating an optimal bonding surface for the paint. This not only results in a more visually appealing finish but also provides protection to the underlying material against potential moisture damage.

- Improved adhesion minimizes the risk of peeling and chipping.

- Enhanced durability enables the paint to withstand various environmental conditions.

- A uniform base guarantees even distribution of color and sheen, thereby elevating the aesthetic appeal.

When carefully selected, primers can greatly enhance the effectiveness of the paint application, ensuring that the desired results are achieved and maximizing the investment in both materials and labor.

How To Paint Silicone Render?

The process of painting silicone render requires a systematic approach. It begins with the application of the first coat using a high-quality paint like Emperor Masonry Paint, followed by a drying period, after which a second coat is applied to achieve a flawless finish.

Apply The First Coat

To initiate the process of painting silicone render, it is essential to apply the first coat of high-quality silicone paint evenly across the surface using appropriate brushes or rollers. Achieving a smooth and uniform application is crucial, as it establishes the foundation for subsequent layers. When applying the initial coat, it is advisable to commence from one corner of the wall and proceed methodically across the surface to avoid any inconsistencies. Ensuring even coverage is vital not only for aesthetic appeal but also for the durability of the finish.

- Select tools that are specifically designed for silicone paint, which typically include high-density foam rollers and quality synthetic brushes.

- Additionally, consider the thickness of the paint, as different applications may necessitate adjustments in the choice of tools.

Maintaining a wet edge during the application process will assist in preventing visible seams and drips, thereby ensuring a professional-looking outcome. By attending to these details during the first coat, one can achieve a beautiful and enduring finish.

Let The First Coat Dry

After applying the first coat, it is essential to allow it to dry completely to facilitate proper curing and ensure optimal adhesion for the subsequent coat.

Typically, the drying time for the first coat may vary from one to several hours, influenced by several factors. Humidity, temperature, and air circulation are critical in determining the drying rate of the paint. For example, elevated humidity levels can significantly prolong the drying time, whereas warmer temperatures tend to expedite the curing process. Understanding these factors is crucial, as they not only affect the drying phase but also the overall integrity of the finished surface.

To optimize the drying process, consider the following recommendations:

- Ensure adequate ventilation to enhance airflow.

- Avoid painting on extremely cold or rainy days.

- Monitor the manufacturer’s guidelines for specific drying times.

Being mindful of these conditions is vital in achieving a flawless finish and preventing issues such as peeling or bubbling in subsequent coats.

Apply The Second Coat

Once the initial coat of paint has dried sufficiently, it is advisable to apply a second coat of silicone paint, such as Johnstones Stormshield, to achieve a more uniform finish and enhance durability.

To ensure optimal results, it is essential to adopt a systematic approach when applying the second coat. Begin by verifying that the first layer is completely cured, as this will prevent issues such as adhesion failure. Utilize a high-quality brush or roller to maintain consistency in thickness across the surface.

Work in manageable sections, paying close attention to corners and edges to avoid drips or unevenness. It may be beneficial to use a paint tray and screen, as these tools can aid in the even distribution of paint on the applicator.

Additionally, consider the temperature and humidity levels, as these factors can significantly affect drying times and paint application.

- Tip 1: Always mix the paint thoroughly prior to commencement.

- Tip 2: Avoid working in direct sunlight to prevent rapid drying.

- Tip 3: If feasible, select a day with mild weather conditions.

By adhering to these guidelines, one can achieve full coverage without omitting any areas, resulting in a professional-looking finish.

Let The Second Coat Dry

After applying the second coat, it is imperative to allow it to dry completely in order to achieve a final finish that aligns with quality standards.

Exercising patience during the drying process is essential, as hurrying this step may result in uneven surfaces, smudges, or potential peeling over time. Environmental factors such as temperature and humidity significantly influence the drying time. For example, a humid environment may extend the drying process, while warmer conditions can accelerate it. It is important to be cognizant of these variables:

- Temperature: Higher temperatures generally expedite drying times, whereas cooler conditions may delay them.

- Humidity: Elevated moisture levels in the air can impede evaporation, consequently prolonging the drying period.

- Airflow: Sufficient ventilation aids in dissipating moisture, facilitating more rapid drying.

By taking these factors into account and allowing adequate time for the second coat to cure, the final result will not only appear professional but will also exhibit durability over time.

How To Maintain The Painted Silicone Render?

Maintaining painted silicone render necessitates regular cleaning, prompt attention to any touch-ups for damaged areas, and reapplication of paint from suppliers as required to preserve its aesthetic appeal and protective properties.

Regular Cleaning (Adaptable To UK weather)

Regular cleaning of painted silicone render is essential for maintaining its low maintenance advantages and preventing the accumulation of dirt, mold, and mildew.

To achieve long-lasting results, homeowners are advised to establish a routine cleaning schedule, ideally twice a year, particularly in areas susceptible to moisture or heavy rainfall. An effective cleaning method involves the use of a pressure washer, which can effectively remove accumulated debris without damaging the render. It is imperative to adjust the pressure settings appropriately to mitigate any potential harm.

In addition, utilizing a solution of water and mild detergent can enhance the cleaning process, particularly for stubborn stains.

- Always commence cleaning from the top and proceed downward to ensure thoroughness.

- The use of soft-bristle brushes is recommended for addressing delicate areas or intricate details.

- A final rinse with clean water will assist in eliminating any soap residues.

By adhering to these recommendations, the render will maintain its aesthetic appeal and structural integrity while minimizing the necessity for extensive repairs or maintenance.

Touch Up Any Damaged Areas

Promptly addressing any damaged areas is essential for preventing further complications and maintaining the overall aesthetic of the painted silicone render.

By swiftly rectifying these imperfections, homeowners can avoid the need for more extensive repairs in the future, which often entail significantly higher costs and greater inconvenience. Upholding a flawless appearance is not solely about immediate visual appeal; it also plays a critical role in the longevity of the structure’s surface.

Utilizing silicone paint for touch-ups is imperative, as it adheres effectively to existing silicone layers, ensuring a uniform finish.

The following is a step-by-step guide for effective touch-ups of your silicone render:

- Assess the Damage: Begin by inspecting the affected areas to ascertain the extent of the damage.

- Clean the Surface: Employ a mild detergent and water to cleanse the area, ensuring it is free of dirt and debris.

- Select the Right Silicone Paint: Choose a silicone-based paint that corresponds to the existing color and finish.

- Apply the Paint: Utilize a small brush or roller to carefully apply the paint, feathering the edges to achieve a seamless blend.

- Let It Cure: Allow the paint to dry completely before subjecting it to moisture or pressure.

Reapply Paint Every Few Years

To preserve the aesthetic and protective qualities of painted silicone render, it is recommended to reapply paint every few years, utilizing high-quality silicone paint from trusted brands like Emperor Masonry Paint for optimal results.

Over time, external factors such as weather conditions, pollution, UV degradation, and physical wear can compromise the integrity of the paint. Consequently, homeowners should remain vigilant for the following signs:

- Fading colors

- Cracking or peeling paint

- Mildew or mold growth

These indicators suggest that the exterior may require attention. Selecting the appropriate paint is essential; it is advisable to choose a high-performance silicone-based product that provides both durability and flexibility.

Additionally, the timing of reapplication is important—consider performing the painting during mild temperatures and low humidity to achieve optimal adhesion and finish quality. Proactive maintenance not only enhances the overall appearance but also serves to protect the underlying render from potential damage.