Curious about resin driveways and how to create one for your home?

We will explore the world of resin, what exactly a resin driveway is, and the numerous benefits it offers.

From durability to low maintenance and aesthetics, resin driveways are a popular choice for many homeowners.

We will also walk you through the step-by-step process of resin driveway installation, the tools and materials needed, and the different types of resin options available.

Let’s dive in and learn all about resin driveways!

What Is Resin?

Resin is a versatile and durable material used in various applications, including the installation of surfaces like driveways, pathways, and more.

One of the key properties of resin is its ability to provide a smooth and seamless finish when used in surface installations, making it a popular choice for both residential and commercial projects. Additionally, resin is known for its resistance to UV rays, chemicals, and extreme weather conditions, ensuring long-lasting performance.

What Is A Resin Driveway?

A resin driveway is a type of surface system that uses a resin bound system or resin bonded system to create a smooth, attractive, and durable surface for driveways and pathways.

Resin bound systems involve mixing resin with aggregates before laying them on a surface, providing a seamless finish that is porous and allows water to drain through, making it eco-friendly.

On the other hand, resin bonded systems consist of scattering loose aggregates onto a resin-coated surface, creating a textured appearance with a strong bond to the existing base.

Resin driveways are highly versatile, available in various colors and designs, offering a modern aesthetic that enhances the overall appeal of any property.

Discover more: Can You Use Epoxy On Driveways

What Are The Benefits Of A Resin Driveway?

Resin driveways offer several benefits, including their advantages in terms of durability, flexibility of design, and ease of maintenance, making them a popular choice for homeowners seeking a reliable and aesthetically pleasing driveway solution.

Durability

One of the standout features of resin driveways is their exceptional durability, which allows them to withstand UV rays, petrol, and oil spills without deteriorating.

Resin driveways are engineered to resist fading and degradation caused by constant exposure to harsh sunlight, making them an ideal long-lasting option for homeowners. In addition, their impermeable surface prevents petrol and oil spills from seeping into the material, unlike traditional tarmac or concrete driveways that can absorb these liquids, leading to stains and structural damage over time.

Low Maintenance

Resin driveways are known for their easy maintenance, significantly reducing issues like moss and weed growth compared to other types of driveways.

This low-maintenance quality is due to the smooth, seamless surface of resin driveways, which leaves no room for weeds to take root. The UV-resistant properties of resin prevent moss from growing, keeping your driveway looking clean and pristine for longer periods.

To maintain your resin driveway, simply sweep it regularly to remove debris. For more stubborn stains, a gentle detergent and water solution can be used to clean the surface. Avoid using harsh chemicals or pressure washers, as they can damage the resin material.

Aesthetics

The smooth surface and flexibility of design inherent in resin surface systems make resin driveways aesthetically pleasing, enhancing the overall look of any property.

These driveways offer a sleek and modern finish that can uplift the curb appeal of a home or commercial space. Customizable design options such as various colors, patterns, and finishes allow property owners to create a unique look that suits their personal style. From classic and elegant designs to more contemporary and bold choices, resin driveways can complement a wide range of property styles.

What Are The Steps To Resin A Driveway?

Installing a resin driveway involves several crucial steps, including proper preparation, ensuring base stability, utilizing a resin bound system, and mixing the resin accurately to achieve the best results.

Preparation

The first step in installing a resin driveway is thorough preparation, which involves ensuring base stability, often using materials like tarmac as a foundation.

Having a stable base is crucial for the longevity and durability of the driveway. Before laying the resin, the existing surface needs to be properly cleaned and leveled to ensure a smooth foundation.

Materials such as tarmac are commonly used due to their ability to provide a strong and reliable base that can withstand heavy traffic and environmental factors. This base layer acts as a solid foundation for the resin to adhere to, preventing cracking or sinking over time.

Mixing The Resin

Properly mixing the resin is a critical step in the resin bound system, and using high-quality materials like those from Derbyshire Specialist Aggregates can ensure a consistent and durable mixture.

When blending resin, it’s crucial to follow the manufacturer’s guidelines meticulously to maintain the desired properties. Be sure to accurately measure the resin and hardener ratio to avoid any curing issues. Consistency is key; a thorough and uniform mixing process prevents any pockets of unmixed resin, leading to a stronger final product. Investing in trusted products such as those offered by Derbyshire Specialist Aggregates enhances the overall performance and longevity of the resin mixture.

Applying The Resin

Applying the resin involves spreading the mixed resin and aggregate evenly across the prepared surface, a task best performed by experienced contractors or installers to ensure a smooth finish.

During the application process, specialized tools like trowels and squeegees are commonly used to achieve the desired evenness and consistency in the coating. These tools help in distributing the mixture uniformly, minimizing the risk of air bubbles or uneven spots on the final surface.

Professional contractors play a crucial role in ensuring that the resin is applied correctly and smoothly, as their expertise allows for precise application techniques that DIY enthusiasts might lack. Their knowledge of the material and techniques can significantly impact the quality and longevity of the finished surface.

Sealing The Driveway

Sealing the driveway is the final step, providing an additional layer of protection to resin surface systems against UV rays and other elements.

When the driveway is sealed, it creates a strong barrier that shields the resin surface from the damaging effects of sunlight, rain, and harsh weather conditions. This protective layer acts as a shield, preventing the resin from deteriorating prematurely and keeping its vibrant color intact for longer periods.

- Sealing the driveway not only enhances the aesthetic appeal but also adds structural strength, making the surface more resistant to cracks, stains, and erosion.

- By sealing the driveway, homeowners can ensure that their investment in a resin driveway pays off in the long run, with reduced maintenance and repairs needed.

What Tools And Materials Are Needed For Resin Driveway?

To install a resin driveway, several essential tools and materials are required, including resin, hardener, aggregate, trowels, rollers, and protective gear, to ensure a successful and safe installation process.

Resin

The type of resin used is crucial, with DALTEX UVR Resin being a popular choice due to its UV stability and durability.

In terms of driveways, harsh exposure to sunlight can often lead to discoloration and degradation of the resin surface. Opting for UV-stable options like DALTEX UVR Resin ensures that your driveway maintains its color vibrancy and integrity over time, even under the intense rays of the sun.

Plus UV stability, it’s essential to consider other qualities in resin products such as strong adhesion properties to ensure long-lasting performance, resistance to chemicals and oils for easy maintenance, and a range of color options to create a customized look that complements your home exterior.

Hardener

A hardener is mixed with the resin to initiate the curing process, which is vital for the resin’s strength and durability.

When the hardener is added to the resin, it acts as a catalyst that triggers a chemical reaction, causing the mixture to harden and solidify. This reaction usually occurs quickly, so it is essential to mix the resin and hardener thoroughly and efficiently. Proper mixing is crucial to ensuring that the hardener is evenly distributed throughout the resin, which guarantees uniform curing and a sturdy final product. Without adequate mixing, the curing process may be uneven, leading to weak spots or improper bonding.

Aggregate

High-quality aggregate, such as those supplied by Derbyshire Specialist Aggregates, is essential for adding strength and aesthetic appeal to the resin driveway.

Choosing the right aggregate is crucial as it directly impacts the durability and overall look of the driveway. The size, shape, and quality of the stones can influence how well the resin binds to them, affecting the structural integrity of the surface. By opting for premium materials from reputable suppliers like Derbyshire Specialist Aggregates, you ensure that your driveway not only lasts longer but also exudes a sophisticated finish that enhances the curb appeal of your property.

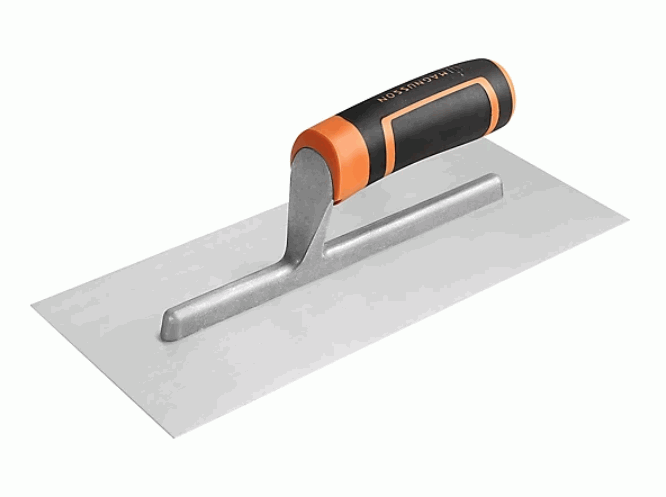

Trowel

A trowel is a key tool used in applying the resin evenly across the surface, ensuring a smooth and consistent finish.

There are various types of trowels available for resin applications, each designed for specific purposes. Notched trowels, also known as serrated trowels, are ideal for spreading adhesives on surfaces, providing an even layer for resin application. Margin trowels, with their small size and pointed shape, are perfect for precise work in tight corners and edges. For achieving a professional finish with a trowel, it’s important to apply even pressure, use smooth and consistent motions, and angle the tool correctly to distribute the resin efficiently.

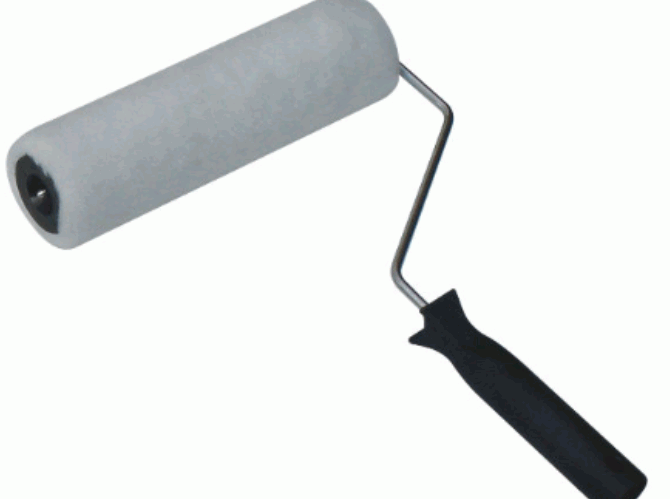

Roller

A roller is often used in the final stages for sealing the driveway, helping to apply the sealant evenly and securely.

Rollers play a crucial role in the sealing process by ensuring a uniform coating of the sealant on the surface. There are various types of rollers available for this task, including foam rollers, nap rollers, and microfiber rollers. Foam rollers are suitable for smooth surfaces, while nap rollers are great for textured surfaces like asphalt. Microfiber rollers work well for applying thicker sealants.

When using a roller, it’s important to start at one end of the driveway and work your way across, applying consistent pressure. Make sure to reload the roller frequently to avoid streaks or missed spots. It’s also recommended to overlap each pass slightly to prevent gaps in coverage.

Protective Gear

Wearing protective gear is essential during the installation of a resin driveway to ensure safety and prevent any health hazards.

There are several types of protective gear that should be worn when working with resin, such as safety goggles to protect the eyes from splashes and fumes, respirators to avoid inhaling potentially harmful vapors, gloves to shield the skin from irritation, and boots to prevent contact with the resin. Each piece serves a critical role in safeguarding the installer against potential risks.

Plus wearing the necessary gear, it is vital to follow general safety tips during the installation process. These include working in a well-ventilated area to minimize fume exposure, reading and following the manufacturer’s instructions carefully, and storing the resin and related materials properly when not in use to prevent accidents.

What Are The Different Types of Resin For Driveways?

There are several types of resin used for driveways, each offering different properties and benefits, making it important to choose the right one for your specific needs and resin surface systems.

Polyurethane Resin

Polyurethane Resin is known for its flexibility of design, making it a popular choice for resin driveways where customization is desired.

One of the key characteristics of Polyurethane Resin is its ability to adapt to various design ideas, offering homeowners and landscapers a wide range of creative possibilities. Its versatile nature allows it to be used to create intricate patterns, textures, and colors, adding a unique touch to any driveway. Moreover, Polyurethane Resin is highly durable and resistant to weather conditions, making it ideal for driveways that need to withstand heavy use and frequent exposure to the elements.

Epoxy Resin

Epoxy Resin is highly durable, making it an excellent choice for driveways that need to withstand heavy use and harsh conditions.

Its robust nature allows it to resist scratches, chipping, and chemicals, ensuring longevity and a well-maintained appearance. The tough surface of Epoxy Resin provides resistance against stains and moisture infiltration, making it a practical choice for high-traffic areas such as garages and industrial settings. This material is specially formulated to endure challenging environments, holding up well under extreme temperatures and heavy loads. The durability of Epoxy Resin contributes to cost-effective maintenance and long-term usability, making it an ideal solution for various demanding applications.

Acrylic Resin

Acrylic Resin offers a balance of durability and ease of installation, making it a versatile option for various types of resin driveways.

One of the standout features of Acrylic Resin is its seamless application process, which appeals to both DIY enthusiasts and professional contractors. Its ability to be easily poured, spread, and molded ensures a hassle-free installation experience. Due to its quick curing time, Acrylic Resin is particularly suitable for projects that require a fast turnaround. Its impressive combination of strength and flexibility ensures that it can withstand the rigors of daily use while still maintaining a level of adaptability to varying weather conditions.